Wet Granulation: High Shear Granulation & Fluid Bed Granulation I

Writer: admin Time:2020-03-24 13:54 Browse:℃

1.Wet granulation

Wet granulation refers to a method to agglomerate powders and granulate them through the adhesion of liquid adhesive which is added into powdery medicines. It can be classified into high shear granulation and fluid bed granulation. Wet granulation acquires advantages like low cost, easy control to content uniformity of tablets or capsules (especially drugs of small size) and improvement of material compressibility through control of bulk density. For these reasons, wet granulation is now applied widely.

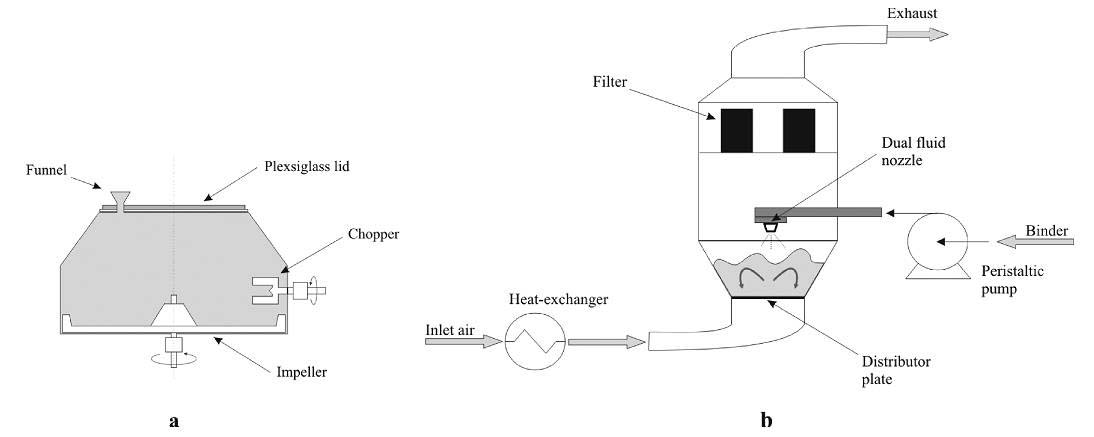

High shear granulation and fluid bed granulation are the two commonest method of wet granulation. But they differ from each other in the fluidity mode of materials. In high shear granulation, the impeller drives materials to overturn in the pot (in figure a.), while in fluid bed granulation, air entering from the bottom of fluid bed contributes to mixing of materials (in figure b.).

2.High shear granulation

High shear granulation consists of two steps, namely mixing (some special materials should be premixed) and granulation. In mixing, the impeller pushes materials to overturn and be mixed in an enclosed pot. And during granulation, adhesive is sprayed downwards. Materials agglomerate and enlarge to granulate and generally, the size of final granules is not so large due to mixing (especially rotating speed of impeller). This is because material blocks can be broken by impeller. As mixing and adhesive spraying continue, adhesive between adherent granules will be removed so that granules harden or enlarge in a new round. We call this situation overgranulation.

High shear can be classified into online drying and offline drying. Most materials are dried offline, i.e. after granulation, they are transferred to other equipment (fluid bed/oven) for drying.

3.Fluid bed granulation

Fluid bed granulation (or fluidized bed granulation) integrates mixing, granulation and drying. Among them, materials are mixed, circulated and boiled through the preheated air entering from the bottom. The circulation is a result of different size of internal and external holes on the bottom plate. Adhesive is sprayed in the direction against air, generally from the top of fluid bed, although adhesive sprayed in the same direction with air is used for coating.

Materials are granulated in fluid bed through two methods: coating and agglomeration. Coating is to spray liquid on the core granules and coat them repeatedly so granules enlarge gradually. Agglomeration refers to that adhesive forms liquid bridge to agglomerate two or more granules into a large granule. In this process, granules wet by adhesive will collide with and attach to their surrounding granules so the granules are linked together though liquid bridge to form large granules. Material drying (by hot air) accompanies fluid bed granulation and last for a longer time than granulation.