Writer: admin Time:2020-10-10 17:38 Browse:℃

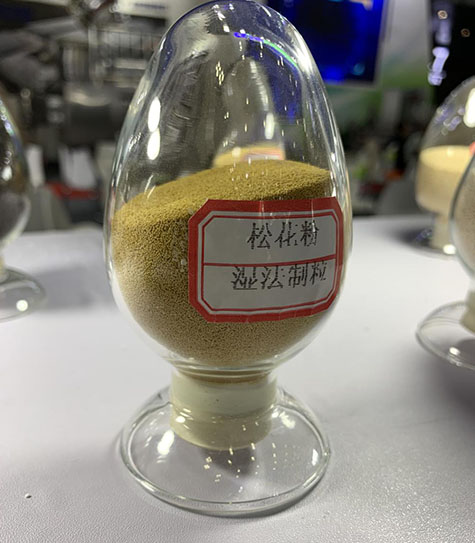

Do you have the problem that your products after fluid-bed granulation become totally powdery without any granule? A netizen once came up with this question online. As he described, the material was some traditional Chinese medicine. Dextrin was first dried in fluid bed granulator for half hour. Then peristaltic pump sprayed extract (relative density: 1.12-1.15, 50°C) into the machine. After these two steps, the final product contains more powder than granules and hence has unqualified granularity.

If this problem occurs in our practical production, how can we solve it? Some other netizen shared their opinions.

Someone suggested to mix part of dextrin with the extract, heat them to 70°C and then spray them into the machine. The temperature can also be adjusted to the proper. Before production, there can be some small test to find out the proper temperature. But the questioner also questioned whether the mixture of the extract with dextrin would clog in the spray gun and influence dissolution of final product. Besides, atomization, flow speed, material temperature and air flow are all critical in granularity control. Sometimes, operators’ operation can also play a part.

Another factor might be the adhesive. Inappropriate adhesive or small amount of adhesive can also lead to low granularity. In addition, it is feasible to wet material more during wet granulation and harden granules more in the drying machine or fluid bed drying machine. But for fluid bed granulation, the operator can make granules larger and harder by adding more water into the mixing barrel and increase spraying flow. Besides, the mesh of screen should be larger.

Anyway, granularity is not singly influenced or determined by a factor. But to sum up, what will influence granularity?

Tel: +86 731 84325468

Phone: +86 13787413551

Email: ava@lkpharmamachinery.com

Whatsapp: +86 13787413551(Ms. Ava)

Add: Ruian city, Zhejiang province