What will influence tablet film coating I

Writer: admin Time:2020-04-01 17:45 Browse:℃

Tablet film coating machine is to coat the polymer onto the tablet to form a layer of film. This process can be explained as: Coating solution is sprayed to the surface of rolling tablets. Hot air then passes through to evaporate solution so that a layer of poly polymer film is formed. In this process, a lot of factors contribute to perfect coating, including form of mist, shock/distribution/aggregation of mist on tablets, and drying of film. Machine designers and operators all need well-knows about them and control them well for high-quality coating.

1)To hide smell of tablets;

2)To improve tablet stability and avoid oxidation caused by light or air;

3)To adjust release of medicine;

4)To separate medicines which are soluble in each other;

5)To shape medicines better.

1.Forming mechanism and influencing factors of film

Film is uneven and different after coating. Unevenness is caused by added insoluble ingredient (such as colorant), besides, film is not formed continuously. In most of coating processes, aggregation solution are sprayed to solid tablets, dried and then sprayed and dried... This process repeats until coating finishes. Therefore, to achieve the best coating effect, its forming mechanism should be understood first.

1)Forming mechanism

The forming mechanism of water-based polymer film is complicated. But as research shows: When being wet, polymer exists in the form of discontinuous particles. However, water is evaporated in drying and those particles become close to each other, transform, aggregate and at last, melt. Therefore, discontinuous film is formed. In these processes, tablets surfaces are wet by thin dispersion. Besides, water volatilizes and polymer particles link to each other. Then water film surrounding particles generates capillary force and accelerate coating. When they invade each other, neighbor particles will aggregate absolutely.

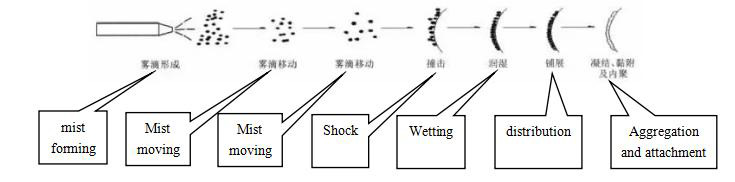

Several important steps in this film coating process include:

Preparation of coating solution or suspension;

Producing of mist;

Movement of mist from generator to tablet container;

Shock, wetting, distribution and aggregation on tablet or particle surfaces;

Dying, gelling, attaching and film forming.

Figure 1 is the schema of the above steps:

2)Influences of physical properties of coating solution or suspension on coating

Physical features of coating solution or suspension can also influence 4 stages of coating. As mist size is found to have effect on coat appearance, people conclude some formula to describe the effect. But those formulas are variable since selected atomizers are different. Therefore, a formula is applicable under certain circumstances. If used in other systems, it will no longer work.

A.In 1974, Fair once proposed to describe influence of solution features on mist size:

DVMSN/DVMST={γSN/γST}0.5*{μSN/μST}0.2*{ρSN/ρST}0.3

In the formula:

SN: solution

ST: solvent

DVM: average size of mist

γ: surface tension of solution

μ: viscosity of solution

ρ: density of solution

B.Nukiyama and Tanasawa came up with formula on mist size in pressure atomization:

Ds={585*103/v}*{γ/ρ}0.5+1683μ0.45{γ*ρ}-0.225{1000/J}1.5

In the formula:

Ds: average surface size of mist

v: air speed at spraying output relative to liquid speed (m/s)

ρ: liquid density (kg/m3)

μ: liquid viscosity (Pa·s)

J: air volume/liquid volume, at spraying nozzle

Actually, the above formula shows that physical properties of solution can influence mist size and size distribution and coating quality. While among physical properties, viscosity, surface tension and density are all vital. For example, surface tension can influence forming of mist. The longer time it takes for mist to move towards tablets, the easier processes of wetting, distribution, penetration and attachment are influenced. And it will further affect coating integrity, tablet adhesion and finish. Besides, viscosity influences solution evaporation speed and aggregation of mist suspending on air.

In practical production, adjusting spraying nozzle and distance can minimum influence of tension on quality.