Product Description

Rolling compactor is a new type of pharmaceutical equipment developed in recent years in the world. It is widely used in pharmaceutical, chemical, food and other industrial production. The raw material is directly dried and dry extruded into granules using only the crystallization water of the material itself .It not only simplifies the process but also improves the quality of the product. At present, the models produced internationally can be basically divided into two types: high pre-compaction type and low pre-compaction type. In terms of appearance, it can be divided into closed and open types. In terms of yield, it ranges from 5 kg per hour to 100 kg per hour. What we introduce here is our company's third generation product Rolling Compactor-100.It is a high pre-compaction type and a closed general-purpose machine applicable for pharmaceutical production and chemical and food industries.

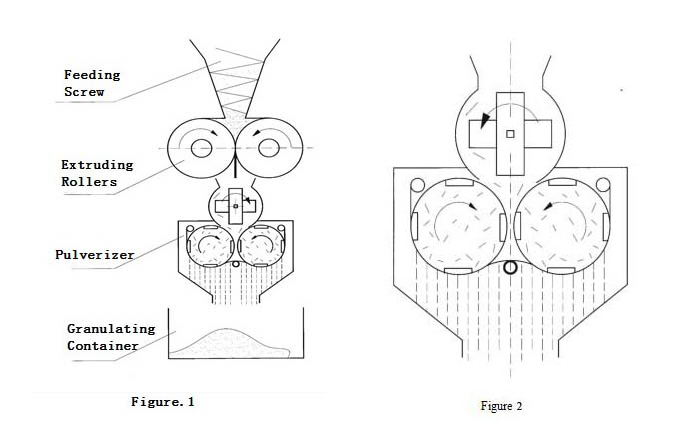

Working Principle

Extrude the powder material into granules under high pressure with the help of the crystallization water of the material itself.

The powder added to the hopper is transported and compressed by a cone-shape unequal pitch screw (the density of the powder is multiplied), and then be pushed onto the two extruding rollers. At this point, the powder is under pressure on five sides. As the extruding rollers rotate, the powder is sent to the gap between the two extruding rollers to be strongly pressed into a hard strip, and then make breaking, screening, and classification.

Advantages

1. This machine is a new equipment that uses the crystal water in the material to make the powder into granules directly.

2. No wetting agents (water or alcohol) needed, to avoid the instability of the produced granules.

3. Saving procedures (wetting, kneading and drying), with high efficiency.

4. Pre-pressing is applied by compression forming, so that high density, uniform weight, and no tablet breakage can be obtained.

5. Small size, easy to be cleaned, GMP requirements can be met.

6. Granule pelletizing after sheet extrusion.

7. Avoid pollution problems such as drainage and air pollution. Uniform granularity, high efficiency and high rotate speed.

8. Wide speed range, multiple uses. It can deal with gummy and greased materials of strong viscosity, high heat sensitivity, poor mobility and high humidity. It also has the advantages of a wide range of granulating mesh.

Characteristics

1.There is no need to use wetting agent as water or alcohol to avoid instability of granule production.

2.As saving the working procedures (wetting, mixing and drying), it has high efficiency.

3.The materials are compressed by pre-pressure to form into good tablets with high density, uniform quality and no fracture phenomenon.

4.The whole machine is made by imported high-quality stainless steel, small and easy to clean, meeting the GMP requirements.

5.It’s suitable for product research & development and small-batch production.

Sample

Main technical parameters

|

Model

|

ZKG-50

|

|

Max Production Capacity

|

10-40KG/h

(will be different according to different material characteristics)

|

|

Granule Specification

|

20-80mesh

|

|

Maxium Thrust

|

10-20T

|

|

Pinch Roller Size

|

φ150*65

|

|

Pinch Roller Rotating Speed

|

0-20rpm

|

|

Feeding Speed

|

0-24rpm

|

|

Crushing Granulation Speed

|

60-180rpm

|

|

Highest Working Oil Pressure

|

15MPa

|

|

Feeding Motor Power

|

0.75KW

|

|

Pinch Roller Motor Power

|

3.7KW

|

|

Crushing Granulation Motor Power

|

1.1KW

|

|

Total Power

|

380V 6KW

|

|

Overall Dimension (L*W*H)

|

1160*1000*1750mm

|

|

Weight (KG)

|

500KG

|