HLSG600 High Speed Wet Super Mixer Granulator Machine Manufacturer

Application

Mixer and Granulator is one of the standard process equipment in the solid dosage production procedure in pharmaceutical industry, and is also widely used in chemical, foodstuff industries,etc. This equipment has function of mixing, granulation and mill.

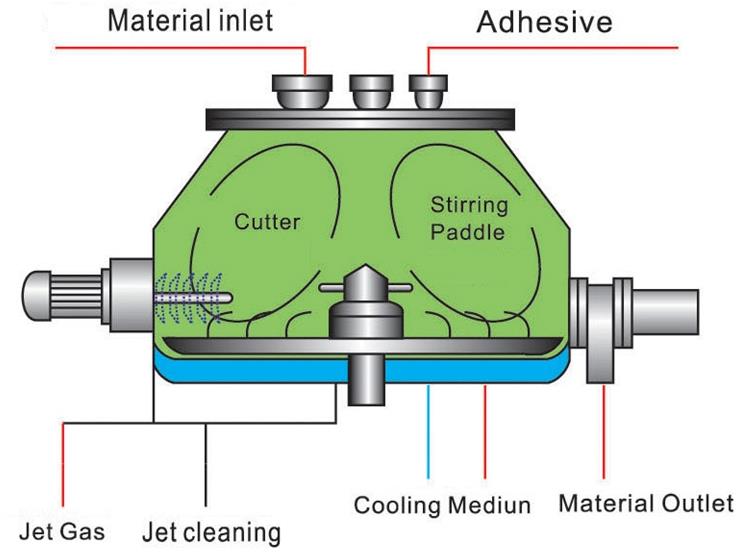

Principle

Charge the materials by pharmacy life or vacuum charging system. Start the procedure, under the action of the impeller, materials are set in a multidimensional shear flow state and thoroughly mixed, Then, the spray gun system sprays the binder solution into the bowl to agglutinate with the materials and, under the combined action of the impeller and chopper, uniform and porous granules are produced. On finishing the granulation process,granules are discharged through the discharge port to the cone mill for homogenization of granules and de - agglomeration of agglomerates.Then, milled granules are discharged to a fluid bed drying application.

Features

This equipment is designed with high platform and hinge mounted cone mill; this type can satisfy more efficiently the process requirements in the solid dosage production procedure. The equipment is made of high quality Austenitic stainless steel and set with operating platform, stepladder and safety guardrail. PLC is designed to ensure a fully automatic control. All the operations are automatically finished according to the customer’s set parameters, moreover, process parameters can be printed and records of original data are truthfully reliable. Furthermore, the hinge mounted cone mill of the mixer and granulator can directly be connected to a fluid-bed processor in a hermetic granulation production line. Mixer and granulator can comply even more with GMP requirements for medicine production.

Advantages

Sample display

Main technical parameters

|

Model |

HLSG-600 |

|

Hopper Volume |

600L |

|

Working Volume |

150-400L |

|

Material Input Quantity (material density is 0.5g/ml) |

75-220KG/batch |

|

Operating Time |

mixing about 8 minutes, granulating 15-20 minutes/batch. |

|

Finished Granule Size |

about Φ0.14-Φ1.5mm

(12-100 meshes)

|

|

mixing motor |

30KW, 6 magnetic poles |

|

Mixing Blade Rotating Speed (frequency conversion speed adjusting) |

20-200 r/min |

|

Granulating Motor |

1.1KW, 2 magnetic poles |

|

Granulating Blade Rotating Speed

(frequency conversion speed adjusting)

|

50-3000 r/min |

|

Compressed Air |

0.3m3, 0.7MPa

(provided by users themselves)

|

|

Cooling Water Connector |

Φ10mm |

|

Compressed Air Connector |

Φ10mm |

|

Overall Dimension of Main Machine (L*W*H) |

2980*1200*2500mm |

|

Weight |

2300KG |

Tel: +86 731 84325468

Phone: +86 13787413551

Email: ava@lkpharmamachinery.com

Whatsapp: +86 13787413551(Ms. Ava)

Add: Ruian city, Zhejiang province