FG-200 All in one lab fluid bed dryer machine with top spray

Sample Display

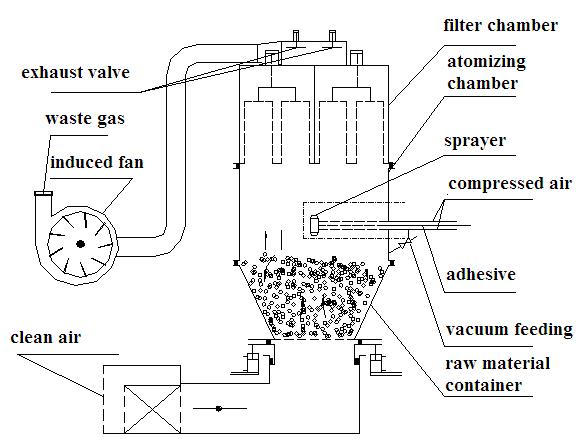

Components

|

System name

|

Components

|

Configurations

|

Material

|

|

Air inlet processing system

|

Filter

|

Primary-efficiency filter (100-mesh SS screen)

|

screen

|

|

Medium-efficiency filter (preposition)

|

Non-woven

|

||

|

High-efficiency filter (heat-resistant)

|

Filter paper

|

||

|

Heater

|

Spiral fin; Steam as heat source

|

SS304

|

|

|

Steam valve

|

Angle seat valve; Switch to control temperature

|

/

|

|

|

Cabinet

|

Double layer for thermal insulation

|

SS304/insulation cotton

|

|

|

Air inlet pipe

|

Offering according to installation; Quick-closing valve is equipped for heat-resistant cylinder

|

SS304

|

|

|

Main machine

|

Filtering chamber

|

Double chamber vibration for cleaning; silicone strip for sealing; anti-rotary device for cleaning cylinder

|

SS304

|

|

Spraying chamber

|

Top spraying: installation base for quick-dismantling spraying gun and sight glass

|

||

|

Base

|

Sealer base; sealed by airbag; hanging; automatic draining valve at the lowest point

|

||

|

Column

|

Double-column; cables are inside the columns

|

||

|

Material feeding port

|

Vacuum feeding valve and sanitary elbow clamp

|

||

|

Observing light

|

To observe material state

|

|

|

|

Control device

|

Pressure reducing valve and air source processing components are all bought from famous brands.

|

/

|

|

|

Air exhaust

|

Induced draft fan

|

Centrifugal and special high-voltage fan (18.5KW); being installed with shock absorber when installed on a floor.

|

Q195

|

Main Technical Parameters

|

Item Parameter |

FL-200 Fluid Bed Dryer |

||

|

Material tank |

Volume |

L |

670 |

|

Diameter |

MM |

1400 |

|

|

Production capacity |

Kg/batch |

160-240 |

|

|

Power supply |

Three-phase |

380V/50HZ or customized |

|

|

Steam |

pressure |

MPa |

0.4-0.6 |

|

Consumption |

Kg/h |

280 |

|

|

Compressed air |

Pressure |

MPa |

0.4-0.7 |

|

Consumption |

Kg/h |

1.2 |

|

|

Draught fan |

Power |

Kw |

22 |

|

Material temperature |

℃ |

Auto-control and auto-display |

|

|

Application range |

|

Mainly used for producing and drying the instant granules, tablets and capsules in both Chinese and western medicines. |

|

|

Obtaining ratio |

% |

≥99% |

|

|

Product moisture |

% |

Can reach 5‰-5% after drying |

|

|

Noise |

db |

With isolating treatment, the noise of draught fan is less than 75 dB. |

|

|

Material |

Stainless steel for all the machine and SUS304 for surface with matte treatment, mirror-polish until Ra 0.3-0.5 inside. |

||

|

Sealing type |

Head pressure type with pneumatic cylinder, good sealing effect. |

||

|

Filtration of inlet air |

It’s equipped with primary, medium and sub-high efficiency filters, so the air filtration level reaches 100000 (3μm). |

||

|

Air capacity regulation |

Frequency control to regulate the air capacity. |

||

|

Steam heater |

Use steam to heat, the material of heater is SUS304 |

||

|

Control method |

PLC control, frequency converter regulating the air capacity, touch screen operating system, Chinese operation interface. |

||

|

Steam angle seat valve |

Famous brand with high temperature control precision. |

||

|

GMP standard |

Designed and manufactured according to GMP standard, in accordance with GMP requirements. |

||

|

Product standard |

According to JB/T13755-92 standard |

||

|

Machine dimension |

Refer to the installation drawing |

||

Tel: +86 731 84325468

Phone: +86 13787413551

Email: ava@lkpharmamachinery.com

Whatsapp: +86 13787413551(Ms. Ava)

Add: Ruian city, Zhejiang province