BG-400D Automatic pharmaceutical film coating machine for tablet

Overview

1. The machine can finish organic film coating, water soluble film coating, slow releasing coating, dripping pill coating and sugar coating to tablets, pills, and candies.

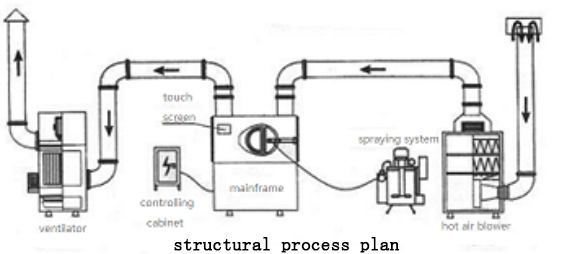

2. Imported PLC, HMI, and touch screen are applied to meet requirements of variable pharmacy technology with advantages of stable operation and performance. They also comply with the standards of GMP.

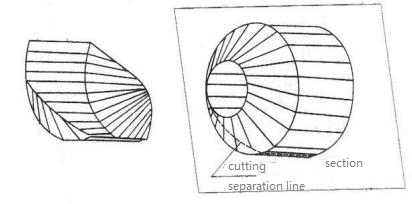

3. Under the force of linear deflector and mixer, tablets reverse fluently, exchange frequently and will not be impacted after falling down from a swell so that tablets keep intact.

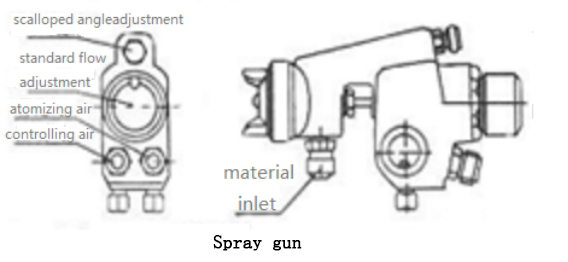

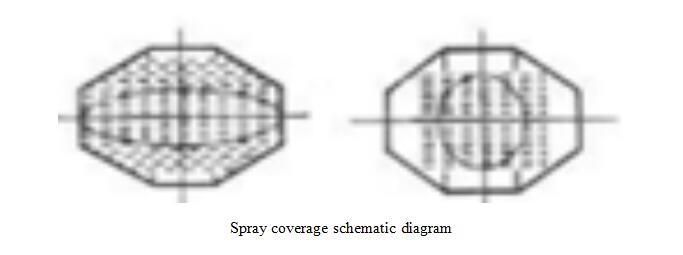

4. Peristaltic pump applies continuous variable frequency conversion. The speed can be adjusted within a range of 0~280 r/min to eliminate defects that resistive speed regulation and voltage speed regulation are not stable, potentiometer is breakable easily, and that rotating speed cannot reach zero because of mechanical speed regulation. Lastly, flame-proof and explosion-proof motor is equipped to fully meet the explosion-proof requirements with stable atomization performance. Spraying system can prevent the spray gun from blockage and can be cleaned conveniently without any dead end.

5. The spray gun acquires advantages of evenly atomization and large spray surface. Besides, the adjustable sprayer will not be influenced by liquid volume.

6. The mixer combines mechanism and electricity in one to avoid chaotic layout of wires and air tubes and to be cleaned more easily.

7. It is newly designed that the negative pressure inside the film coating pan can be measured and adjusted automatically to improve the coating quality but save energy.

8. Hot air blower and ventilator are equipped with shockproof and silencing equipment to lower the operation noise of the complete machine and to not harm health of operator.

9. Temperature value is displayed and temperature can be controlled.

10. The function of cleaning guns to avoid blockage is acquired.

About BG-400

1. Production capacity: 400Kg end product per pan (the same with sugar coating and organic film coating).

Note: The film coating cylinder volume for material is about 400L, counted by the volume between the bottom and the lower edge of cylinder. However, practical operating volume is 350-400L, while the maximum density of material is 1.0Kg/L. Thus, the final weight can be counted to 400Kg.

2. The machine can film Chinese and Western tablets, pills, and candies with organic film, water soluble film and sugar coating. The coating quality complies with pharmacopoeia of China. The machine has served for hundreds companies to produce several hundred medicines complying with the requirements of pharmacy.

3. The equipment surfaces are all treated.

1) The film coating roller and mixer contacting with tablets are made from stainless steel of good quality, such as AISJ316L, etc.. Internal and external surface of the roller, and the mixer have all been treated with mirror finish with Ra ≥ 1.6. Generally, Ra = 0.8.

2) Other equipments are made from stainless steel and comply with the standards of GMP. Film coating operates in a absolutely closed environment. The complete machine with a stainless steel dustcoat is closed and acquires advantages of convenient cleaning, good sealing, no leaking and no dust.

3) The external surface of the complete machine is treated with matt and decorated with horizontal stripes.

4. About the mainframe:

1) The speed of roller can be adjusted within 2-16 r/min with error of ± 0.5r/min

2) The internal and external surface of the pan is smooth, and the orifice and sieve are all flat without glitch. The bucket is treated with mirror finish internally and externally to be smoothly connected without any dead end.

5. Controlling system

1) FBE-40MC PLC produced by FACON, Taiwan and Pro-face touch screen produced by Digitac are applied so that almost all operations can be finished on the touch screen.

2) Functions of remote monitoring and access controlling can be equipped.

3) The system components are all produced by famous manufacturers at home and abroad with strong anti-interference ability to make the system operate stably and steadily.

4) The power cabinet separates from the mainframe.

6. Others:

1) Electrical safety performance complies with the regulations of GB5226.1.

a) Electrical component controlling and power circuit insulation cathode should not be less than 1MW.

b) Electricity consists of external electrical components and controlling and a voltage test when the power circuit reach 100V AC, 50Hz.

2) The film coating roller operates stably with noise no more than 65Db (A)

3) The motor applied in ventilating and infusing equipments should be explosion proof. And the fan blades are made from aluminum alloy which is explosion proof too.

Innovative Technology

The invention, discovery and innovation mainly reflect in the following aspects:

I. Spraying system equipment:

II. Hot air blower and ventilator are equipped with shock-proof and silencing equipments to lower the operating noise obviously and protect the health of operators.

III. PLC is applied to design HMI and screen displaying and operating system. Operators can set programs and adjust and control variable parameters during film coating through human-machine dialogue box. Therefore, automatic operation can be fulfilled throughout the process.

IV. The mixer combines mechanism and electricity in one to avoid chaotic layout of wires and air tubes and to be cleaned more easily.

Main Technical Parameters

| Model | BG-400D high efficiency film coating machine | ||

| Motor | Maximum medicine loading capacity | 400Kg | |

| Roller rotating speed | 2-13r/min | ||

| Roller diameter | 1600mm | ||

| Mainframe power | 3KW | ||

| Damper valve body motor power | 90W | ||

| Compressed air | 1.5m³/m Pressure ≥0.5MPa | ||

| Mainframe dimensions | 2060*1680*2590mm | ||

| Imported spray gun with adjustable spraying shape, flow, distance and angle. | |||

| The machine can be operated through HMI and controlled through PLC. | |||

| High efficiency filtering shock-proof hot air blower | Filtering hot air blower power | 3KW | |

| Air intake | 2664/5268m³/h | ||

| Filtering accuracy is 5μm Primary, intermediate, high efficiency filtering 100,000 class clean air | |||

| The external surface of hot air blower is made from matt stainless steel | |||

| Hot temperature | Adjustable within the room temperature (>0°C) to 80°C | ||

| Total steam consumption | 130Kg/h Pressure: ≥0.4MPa | ||

| Dimensions | 910*2500*1100mm | ||

|

Dust removal, shock-proof and silencing ventilator |

Dust removal ventilator motor power | 7.5KW | |

| Dust removal vibrating motor power | 0.25KW | ||

| Air outtake | 10000m³/h | ||

| The external surface of ventilator is made from matt stainless steel | |||

| Dimensions | 1050*1050*2300 | ||

| Insulation mixer | Model | TB-130 Including pneumatic motor, air distributor, air filtering pressure reducing valve | |

| Riot electrical heating | 4KW | ||

| Volume of mixing drum | 130L | ||

| Appropriate medium | When medium concentration is less than 4%, viscosity is less than 200cst. When medium concentration is less than or equal to 14%, viscosity is less than 10cst. | ||

|

Remote controllable explosion-proof peristaltic pump |

Model | PR-4 | |

| Motor power | 54W | ||

| Rotating speed | 1-600r/mi | ||

| Maximum flow | 3.6L/min (water as the medium) | ||

| One of each for material inlet and out let equipments, discharger, material outlet hopper and material inlet hopper | |||

| Air tube diameter | 310mm | ||

| Material | SUS#304 | ||

| Total power supply | Steam heating | 20KW | |

| Electrical heating | 60KW | ||

Technical Parameters

|

Items |

Parameters |

|

|

Model |

BG-400D |

|

|

Production quantity |

400Kg every batch |

|

|

Speed range of film coating roller |

2-11r/min |

|

|

Diameter of material inlet |

580mm |

|

|

Diameter of film coating roller |

1560mm |

|

|

Diameter of roller mesh |

3mm |

|

|

Motor power of mainframe |

4KW (The mainframe is totally closed) |

|

|

Air source (supplied by the user) |

1.5 m3/min Pressure: ≥0.4MPa. |

|

|

Main Machine Dimension |

2050*1680*2500 (L*W*H) | |

|

PLC |

It can make the frequency conversion continuously variable and set, adjust, display and memorize the technical parameters, operation speed, air inlet speed, spray force and flow during the operation of the complete machine. |

|

|

Hot air cabinet |

Motor power of hot air filter |

3KW (explosion-proof) |

|

Filter precision |

0.5μm |

|

|

Filter cleanliness |

100,000 class |

|

|

Air inlet speed |

5660m³/h (with a class-3 filter) |

|

|

Hot air temperature |

40~80℃ (adjustable) |

|

|

Dimensions |

1080*820*2500mm (L*W*H) |

|

|

Weight |

400Kg |

|

|

Dust removal cabinet |

Motor power dust removal fan |

7.5KW (explosion-proof) |

|

Air outlet speed |

17810 m3/h |

|

|

Surface material |

Matt stainless steel |

|

|

Dimensions |

1140*1140*2120mm (L*W*H) |

|

|

Weight |

500Kg |

|

|

Spray gun |

Imported spray gun with uniform atomization, adjustable spray shape, position and angle |

|

|

Motor power of peristaltic pump |

54KW |

|

|

Peristaltic pump speed |

100-700 r/min |

|

|

Mainframe weight |

1650Kg |

|

Tel: +86 731 84325468

Phone: +86 13787413551

Email: ava@lkpharmamachinery.com

Whatsapp: +86 13787413551(Ms. Ava)

Add: Ruian city, Zhejiang province