1.Overview

SZ series wet (dry) sieving and milling machine can be applicable in industries of pharmacy, food, fine chemicals processing. It can be used as dry cone mill or wet sieving and milling machine, by changing the milling knife. All of the wet material sieving and milling and processing equipment, wiring and machine line can meet the standards of GMP. Besides, the complete machine is made of stainless steel.

2.Operation principle

Materials to be processed enter the cone operation chamber through the material inlet port of the machine. Then rotating knife will make raw materials turn around and flow and will throw granules to the sieve under the centrifugal force. At the same time, the rotating knife rotate in a high speed to produce a shearing force together with the sieve. As a result, granules will be broken into small particles between the rotating knife and sieve and output through the sieve holes. The size of particles depends on the sieve mesh quantity, the gap between rotating knife and sieve and the rotating speed.

Main Technical Parameters

|

Item Mode

|

SZ-300

|

|

Motor power

|

KW

|

3.7

|

|

Output

|

Kg/h

|

50-300

|

|

Sieve hole diameter

|

Mm

|

3*(3-8)*8 (optional)

|

|

Rotating speed

|

Mm

|

Frequency control to the max of 1400

|

|

Rotating speed of the knife

|

r/min

|

200~1400

|

|

Overall dimensions

|

r/min

|

/

|

|

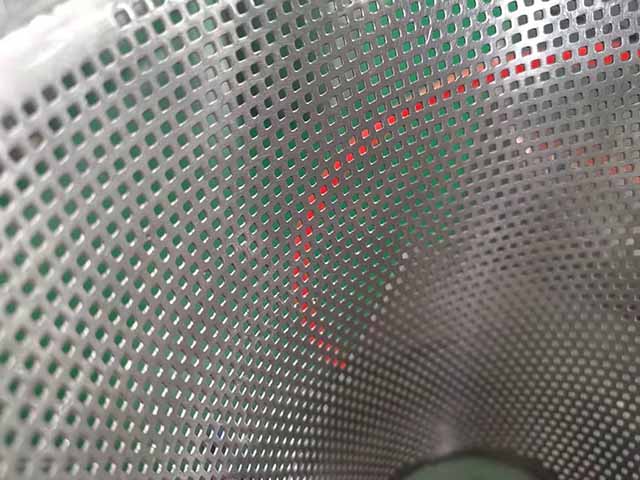

Sieve shape

|

Square: applicable in wet sieving and milling

|

|

Sieve shape

|

Round: applicable in dry sieving and milling

|

Machine and parts photos

wet sieving and milling machine blade

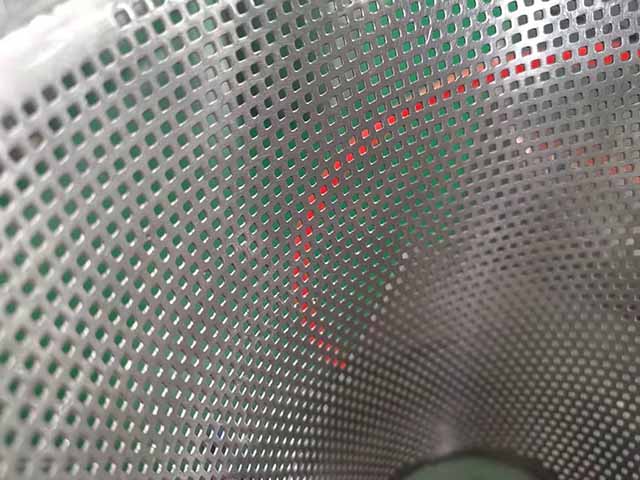

Screen mesh of the wet sieving and milling machine

wet sieving and milling machine, this is made to be an individual separated machine, not connected with the wet granulation machine.

Wet sieving and milling machine to connect with the wet granulation machine, it will also help to connect with the fluid bed dryer to realize a full automatic production line.

Sample photos