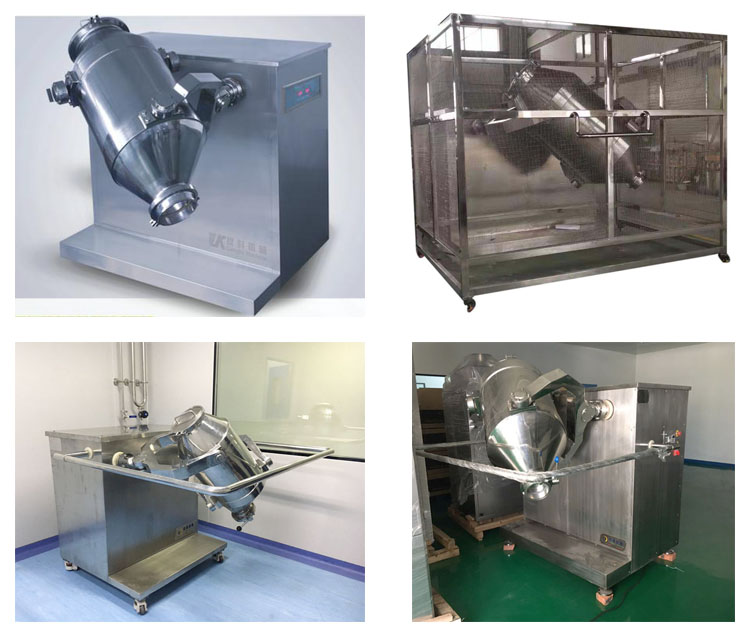

Three dimensional mixer

Main Technical Parameters

|

specification |

Maxing bucket volume (L) |

Maximum material volume (L) |

Motor power (KW) |

Rotating speed (r/min) |

Weight (Kg) |

Standard height of material outlet (mm) |

Standard height of material inlet (mm) |

Dimensions (dynamic) |

|

HD 5 |

5 |

4 |

0.5 |

≤25 |

70 |

280 |

800 |

1010*670*670 |

|

HD 25 |

25 |

20 |

0.75 |

≤22 |

100 |

260 |

820 |

1010*670*670 |

|

HD 50 |

50 |

40 |

1.5 |

≤16 |

200 |

500 |

1200 |

1190*1090*1450 |

|

HD 100 |

100 |

80 |

2.2 |

≤15 |

500 |

600 |

1570 |

1580*1260*1600 |

|

HD 200 |

200 |

170 |

2.2 |

≤14 |

700 |

600 |

1680 |

1920*1550*1920 |

|

HD 400 |

400 |

340 |

4 |

≤13 |

1200 |

630 |

1900 |

2270*1670*2170 |

|

HD 600 |

600 |

500 |

5.5 |

≤13 |

1500 |

630 |

2100 |

2470*1860*2270 |

|

HD 800 |

800 |

680 |

7.5 |

≤10 |

2500 |

780 |

2300 |

2840*2200*2470 |

|

HD 1000 |

1000 |

850 |

7.5 |

≤10 |

2600 |

700 |

2450 |

2950*2150*2530 |

|

HD 1500 |

1500 |

1250 |

11 |

≤8 |

3000 |

850 |

2800 |

3403*2700*3120 |

Sample display

Tel: +86 731 84325468

Phone: +86 13787413551

Email: ava@lkpharmamachinery.com

Whatsapp: +86 13787413551(Ms. Ava)

Add: Ruian city, Zhejiang province