V shape blender is an asymmetric machine of high efficiency. It is generally applicable in chemical, food, pharmaceutical, fodder, ceramic or metallurgical industries to mix powdery or granular materials. It features reasonable and simple structure, operation in closed environment, convenient feeding and discharging, manual or vacuum material feeding... Its container is made of stainless steel and can be cleaned easily. Many enterprises adopt it as the basic equipment for granulation.

|

model

|

CH-6000V

|

CH-4000V

|

CH-2500V

|

CH-1500V

|

CH-1000V

|

CH-500V

|

CH-300V

|

|

production capacity (kg/time)

|

2500

|

1800

|

1200

|

680

|

400

|

200

|

100

|

|

model of vacuum pump

|

W4

|

W4

|

W3

|

W3

|

W3

|

W2

|

W2

|

|

material feeding time (min)

|

10-15

|

10-15

|

8-12

|

6-10

|

6-9

|

4-6

|

4-6

|

|

mixing time (min)

|

8-15

|

8-15

|

8-15

|

8-15

|

8-15

|

8-15

|

8-15

|

|

volume(m³)

|

6.0

|

4.0

|

2.5

|

1.5

|

1.0

|

0.5

|

0.3

|

|

rotation speed of mixing barrel(rpm)

|

10-12

|

10-12

|

10-12

|

10-12

|

10-12

|

10-12

|

10-12

|

|

motor power(kw)

|

15

|

11

|

7.5

|

4

|

4

|

2.2

|

1.1

|

|

height of mixing barrel

|

4380

|

4200

|

3790

|

3100

|

3000

|

2450

|

1850

|

|

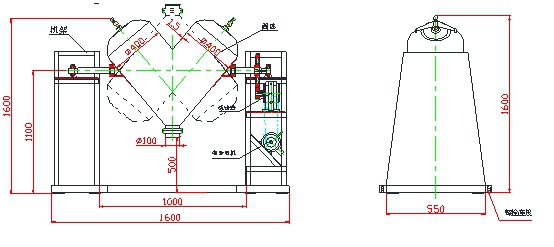

overall dimensions (L*W*H)

|

4500×2200×4380

|

4300×2080×4200

|

3990×1990×3790

|

3190×1600×3100

|

2975×1600×3000

|

2500×1200×2420

|

1880×650×1850

|

|

weight (KG)

|

3200

|

2800

|

2040

|

1020

|

950

|

550

|

320

|

Tel: +86 731 84325468

Phone: +86 13787413551

Email: ava@lkpharmamachinery.com

Whatsapp: +86 13787413551(Ms. Ava)

Add: Ruian city, Zhejiang province