100kg per batch Solid dosage production line

This production line is to produce solid dosage around 100kg per batch, it is consist of QVC-3 vacuum feeder,HLSG-300 super mixer granulator,SZ-500 Wet Type Pelletizer andFL-120 Fluid Bed Granulating Drier

Production plant

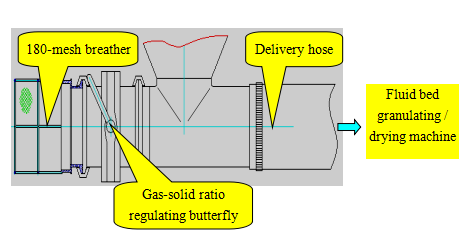

QVC-3 vacuum feeder( to match with super mixer)

|

Model |

Conveying volume kg/h(maximum) |

Air consumption(L/M) |

Air pressureMPa |

Overall dimension |

|

QVC-3 vacuum feeder |

800-1500 |

720 |

0.4-0.6 |

¢290×850 |

main photo

Main Technical Parameters

|

Model |

HLSG-300 |

|

Hopper Volume |

300L |

|

Material input quantity |

60-240L/30—120KG/batch (the material density is 0.5 g/ml) |

|

Operational time |

Mixing about 5 minutes, granulating 3-15 minutes for each batch. |

|

Finished granule size |

About Φ0.14-Φ1.5mm(12 holes-100 holes) |

|

Hybrid motor |

18.5KW 6 magnetic poles |

| Revolution speed of mixing paddle (controlled by frequency converter) |

30-220 r/min |

|

Granulating motor |

5.5KW 2 magnetic poles |

|

Revolution speed of granulating blade (controlled by frequency converter) |

50-3000 R/Min |

|

Compressed air |

0.3 m3 0.7Mpa(Collocated by customer themselves) |

|

Cooling water connector |

Φ10mm |

|

Compressed air connector |

Φ10mm |

|

Height of discharge port |

985mm |

|

Main frame dimension (L×B×H) |

2420×1060×2150mm |

|

Weight |

1600kg |

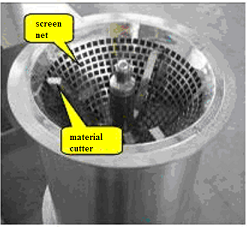

SZ Series Wet Type Pelletizer

SZ-500 Wet Type Pelletizer

Technical Parameters

|

Model |

SZ-500 |

|

Motor power(KW) |

4 |

|

Production capacity(Kg/h) |

80-300 |

|

screen mesh size(Mm) |

3×3-6×6(choose any one) |

|

Revolution speed(rpm) |

The maximum speed can be regulated to 1600 by frequency converter. |

|

Revolution speed of cutter(rpm) |

200~1600 |

|

Screen net shape for blader |

Square: suitable for wet granules pelletizing |

FL-120 Fluid Bed Granulating Drier

Machine Photo

Main Technical Parameters

|

Item Parameter |

FL-120 Fluid Bed Granulating and Coating Machine |

||

|

Production capacity |

Kg/time |

60-120 |

|

|

Power supply |

Three-phase |

380V/50HZ |

|

|

Electrical heating |

power |

Kw |

70 |

|

Consumption |

Kg/h |

25 |

|

|

Compressed air |

Pressure |

MPa |

0.5-0.7 |

|

Consumption |

Kg/h |

0.8 |

|

|

Draught fan |

Power |

Kw |

18.5 |

|

Material temperature |

℃ |

Auto-control and auto-display |

|

|

Application range |

|

Mainly used for producing and drying the instant granules, tablets and capsules in both Chinese and western medicines. |

|

|

Obtaining ratio |

% |

≥99% |

|

|

Product moisture |

% |

Can reach 5‰-5% after drying |

|

|

Noise |

db |

With isolating treatment, the noise of draught fan is less than 75 dB. |

|

|

Material |

Stainless steel for all the machine and SUS304 for surface with matte treatment, mirror-polish until Ra 0.3-0.5 inside. |

||

|

Sealing type |

Head pressure type with pneumatic cylinder, good sealing effect. |

||

|

Filtration of inlet air |

It’s equipped with primary, medium and sub-high efficiency filters, so the air filtration level reaches 100000 (3μm). |

||

|

Air capacity regulation |

Frequency control to regulate the air capacity. |

||

|

Heating method |

Electrical heating, heater material to be SUS304 |

||

|

Control method |

PLC control, frequency converter regulating the air capacity, touch screen operating system, Chinese operation interface. |

||

|

Controlled silicon |

Famous brand with high temperature control precision. |

||

|

GMP standard |

Designed and manufactured according to GMP standard, in accordance with GMP requirements. |

||

|

Product standard |

According to JB/T13755-92 standard |

||

|

Machine dimension |

Refer to the installation drawing |

||

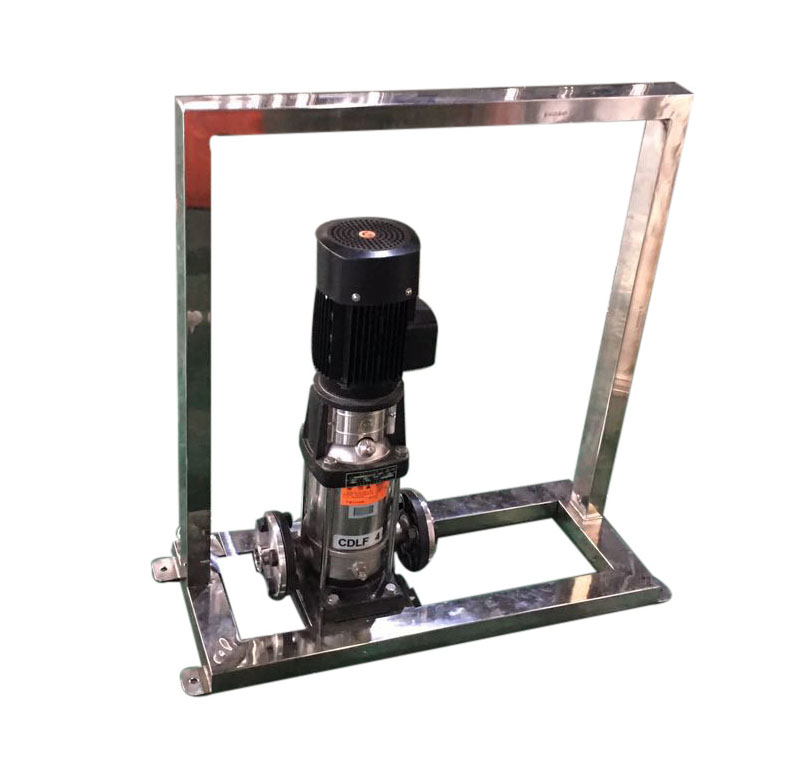

Brief introduction of CIP one-way cleaning system

The cleaning machine consists of main frame, water pipeline, cleaning ball, high-pressure booster pump, control valve and control system. After quick-connecting the water inlet of cleaning machine with customer’s water inlet pipe, start the cleaning procedure to finish this process automatically.

Sample

Wenzhou Liangke Machinery has specialized in production of solid preparation process machine for more than 20 years, including wet granulator, roll compactor, fluid bed dryer, mixer, tablet press, coating machine, capsule filling machine etc. Also engaged in pharmaceutical trade,chemical trade as well as food trade with qualified team and mature technology.

Tel: +86 731 84325468

Phone: +86 13787413551

Email: ava@lkpharmamachinery.com

Whatsapp: +86 13787413551(Ms. Ava)

Add: Ruian city, Zhejiang province