30kg Per batch Solid Dosage Granulation and Drying Production Line

This production line is designed for the small scale solid dosage around 30kg, it is combined from the HLSG100 High efficiency wet granulator, SZ300 wet sieving and milling machine, FL30 Fluid bed granulating dryer. It is suitable for the small scale production of solid dosage product.

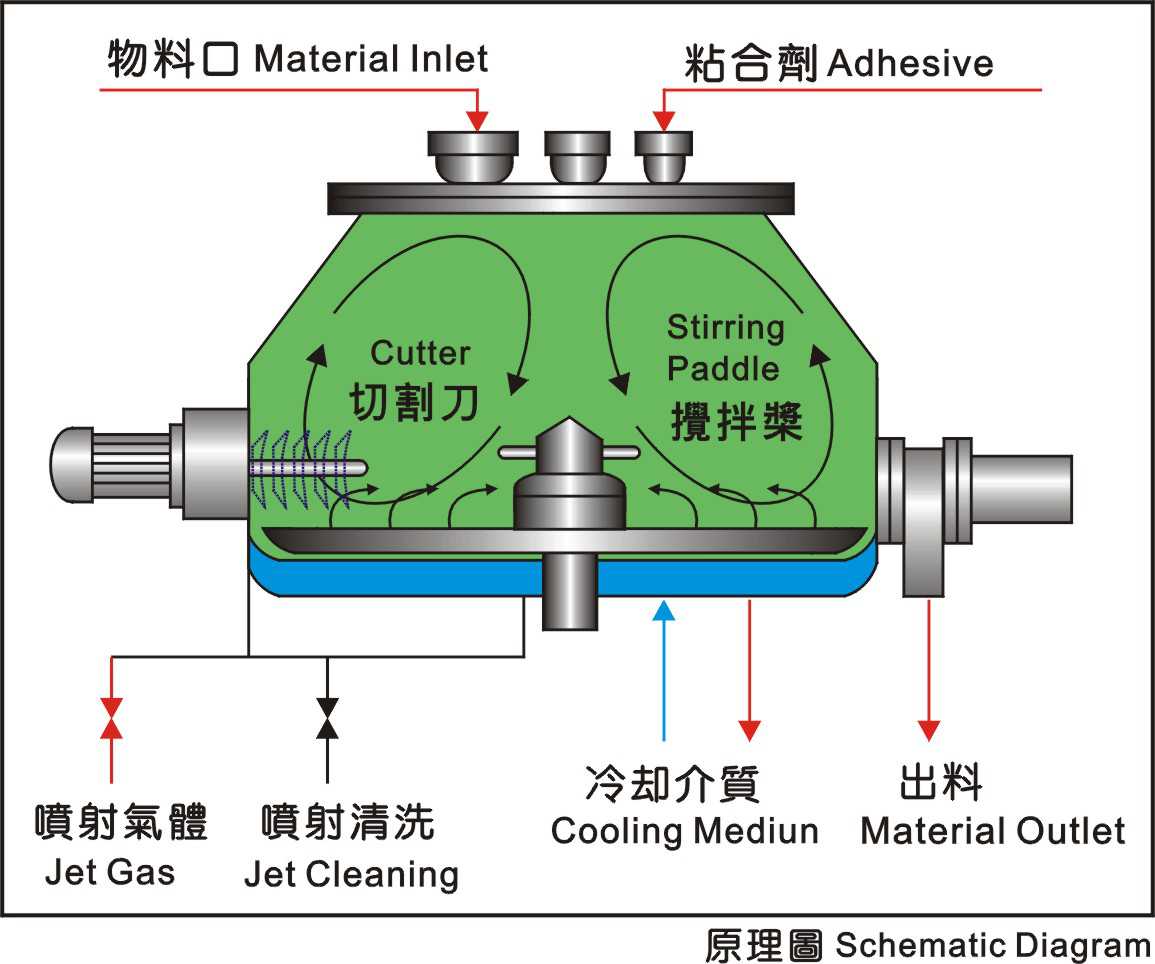

HLSG-series High Efficiency Wet Granulator

Overview

Our company, as a company specialized in the development, manufacture, sale and service of pharmaceutical machine, is awarded as a creditable enterprise , and rated as Credit A company. Some other awards are “ Developing Technical SME in Zhejiang Province”, “Technical SME in Zhejiang Province”, “Technical (Innovative) Enterprise in Wenzhou”. Besides, Our equipments have passed the CE Qualification Certification of EU. In addition, our machines are sold to many provinces and cities of China and to parts of America, Europe, Oceania, West Asia and South-east Asia.

Main Technical Parameters

|

Model and specification |

HLSG-100 |

|

Hopper capacity |

100L |

|

Material feeding volume |

30-80L |

|

Operation time |

5min/batch for mixing

3-15min/batch for granulation

|

|

End product diameter |

About Φ0.10-Φ2.5mm |

|

Mixing motor |

7.5KW, 6 poles |

| Rotating speed of mixing shaft (frequency control) |

30-250rpm |

|

Granulating motor |

3KW, 2 poles |

|

Rotating speed of granulating shaft (frequency control) |

50-3000rpm |

|

Compressed air |

0.3m3, 0.7MPa |

|

Cooling water connector |

Φ8mm |

|

Compressed air port |

Φ8mm |

|

Overall dimensions (L*B*H) |

1760*600*1660mm |

|

Weight |

About 800Kg |

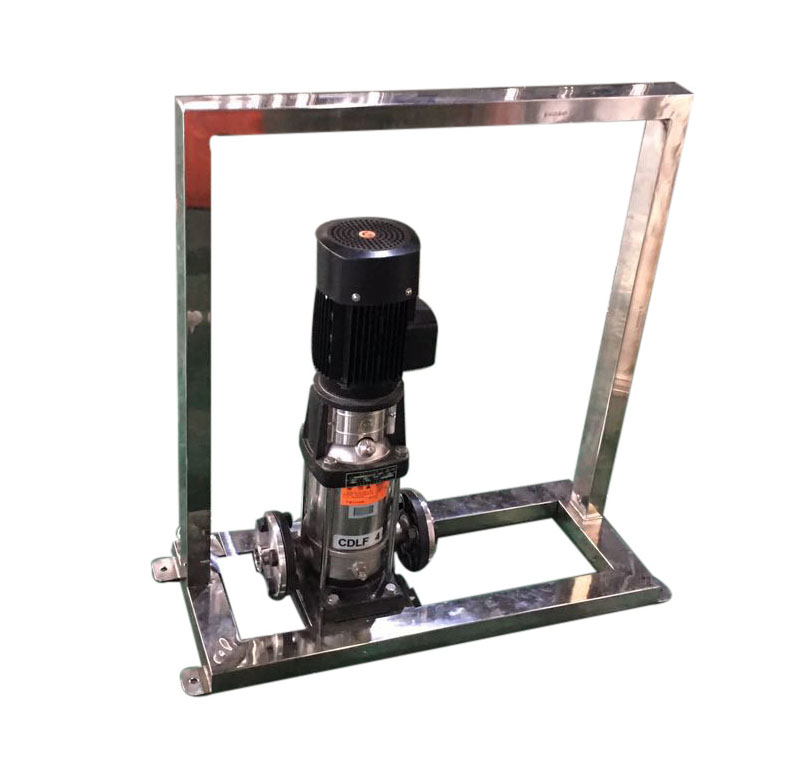

LJY-30 Automatic Liquid Feeding System

Technical Parameters

|

Model |

LJY-30 |

|

Operation volume |

30L |

|

Mixing rotating speed (pneumatic mixing) |

10-300rpm |

|

Air consumption |

0.3-0.5m3/h |

|

Overall size of bucket |

350*450 |

|

Operation air pressure |

0.4-0.6MPa |

|

Machine weight |

50Kg |

Main Technical Parameters

|

Item Mode |

SZ-300 |

||

|

Motor power |

KW |

3.7 |

|

|

Production capacity |

Kg/h |

50-200 |

|

|

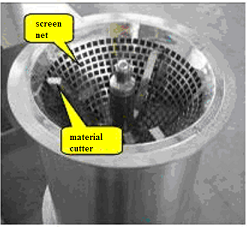

screen mesh size |

Mm |

2*2-6*6(choose any one) |

|

|

Revolution speed |

rpm |

The maximum speed can be regulated to 1600 by frequency converter. |

|

|

Revolution speed of cutter |

rpm |

200~1600 |

|

|

Screen net shape for cutter |

Square: suitable for wet granules sieving and milling |

||

Technical Parameters

|

Item Parameter |

FL-30 fluid bed dryer |

||

|

Material container |

Volume |

L |

110 |

|

Diameter |

M |

750 |

|

|

Production capacity |

Kg/time |

15-30 |

|

|

Power supply |

Three-phase |

380V/50HZ |

|

|

Electrical heating power |

Kg |

27 |

|

|

Compressed air |

Pressure |

MPa |

0.4-0.7 |

|

Consumption |

Kg/h |

0.5 |

|

|

fan |

Power |

Kw |

11 |

|

Material temperature |

℃ |

Auto-control and auto-display |

|

|

Application |

|

Applicable to produce and dry Chinese medicine, medical granules, tablet granules, capsule granules |

|

|

Yield rate |

% |

≥99% |

|

|

Product moisture |

% |

1%-5% after drying |

|

|

Noise |

db |

Less than 75db since fan is separated |

|

|

Material |

Stainless steel for all the machine and SUS304 for surface with matte treatment, mirror-polish until Ra 0.3-0.5 inside. |

||

|

Sealing mode |

Cylinder top sealing of good effect |

||

|

Air inlet filter |

With primary, medium and sub-high efficiency filters, so the air filtration level reaches 100000 grade (3μm). |

||

|

Airflow control |

Frequency control |

||

|

Heater |

Heating mode: electrical heating / Heating material: SUS#304

|

||

|

Control method |

PLC control, frequency converter regulating the air capacity, touch screen operating system, Chinese operation interface. |

||

|

GMP |

Designed and produced under requirements of GMP to comply with them |

||

|

Product standard |

JB/T13755-92 |

||

|

Noise |

db |

Less than 75db since fan is separated |

|

|

Overall dimensions |

Seen in the installation floor plan

|

||

Wenzhou Liangke Machinery has specialized in production of solid preparation process machine for more than 20 years, including wet granulator, roll compactor, fluid bed dryer, mixer, tablet press, coating machine, capsule filling machine etc. Also engaged in pharmaceutical trade,chemical trade as well as food trade with qualified team and mature technology.

Tel: +86 731 84325468

Phone: +86 13787413551

Email: ava@lkpharmamachinery.com

Whatsapp: +86 13787413551(Ms. Ava)

Add: Ruian city, Zhejiang province